Dantek and flotation using micro-nano bubbles DAF

When billions upon billions of micro and nano bubbles float whatever it is

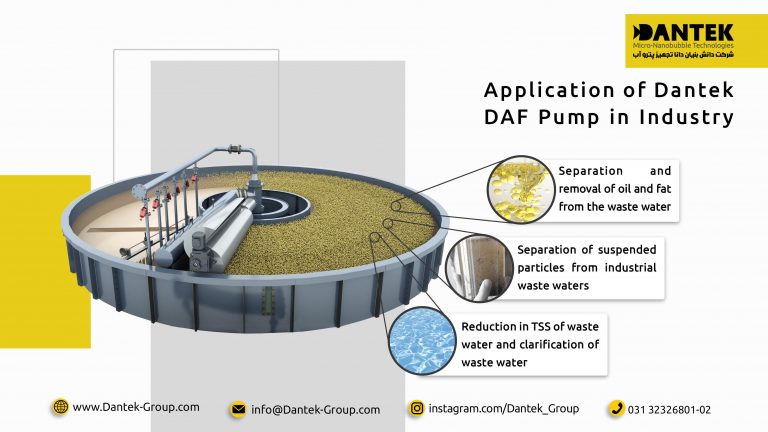

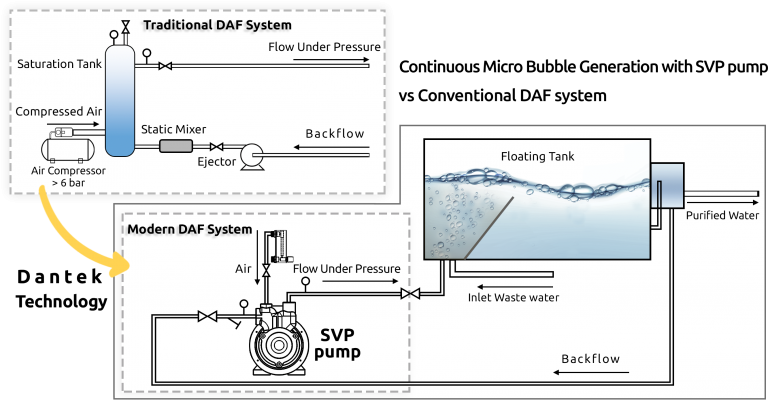

In industrial wastewater treatment, soluble air flotation systems or DAF systems are used to float suspended particles in the fluid, remove grease and oil. In conventional DAF systems, air bubbles are generated by a multi-stage mechanism and enter the flotation tank, floating suspended particles and fats on the surface of the water. Bubble production in conventional flotation systems is done using various equipment such as resuscitation pump, air compressor, pressure tank, static mixer, air dissolution tank and pressure relief valve. Unlike traditional systems, in the new generation of DAF systems, using a two-phase vortex pump, aeration and water circulation operations can be performed, and finally bubble production can be performed without the need for a compressor, resuscitation pump and other accessories. In fact, by using this two-phase vortex pump without the need for compressors, static mixers, saturated pressure tanks, ejectors, safety valves, small bubbles can be produced with very high density, and in terms of equipment and economic efficiency is very cost effective compared to conventional systems. In addition, the bubbles produced by this pump are in micrometers and nanometers and have a very good ability to float suspended particles, even in very small dimensions.

Flotation

Micro-nano-bubbles are characterized by an increase in the surface-to-volume ratio. This phenomenon leads to more contact with the particles in the solution, resulting in flotation and removal of more particles than conventional bubble generating systems. Increasing the collision rate leads to the formation of large masses with minimal need for the use of coagulants and chemicals (coagulants and flocculants). The efficiency of fat removal in emulsion mode using nano-bubbles is much higher than ordinary bubbles.

The low velocity of bubbles rising to the surface of the water is another unique feature of micro-nanobubbles that distinguishes them from ordinary bubbles. Under these conditions, bubbles have more opportunity to carry particles to the surface of the water, and nanobubbles will have a high diffusion property due to the brown movement in water. This phenomenon causes more bubbles to collide with the particles, and as a result, more particles in the water are brought to the surface than ordinary bubbles.

Advantages of using a two-phase vortex pump for flotation of particles

- Reduce the use of chemicals for flocculation

- Micronano-scale bubble production immediately after turning on the two-phase vortex pump compared to conventional DAF systems

- Improved BOD, cod, TSS, oil removal, grease and water color parameters compared to conventional DAF systems

- Occupy little work space

- Minimum maintenance required

- Low energy consumption