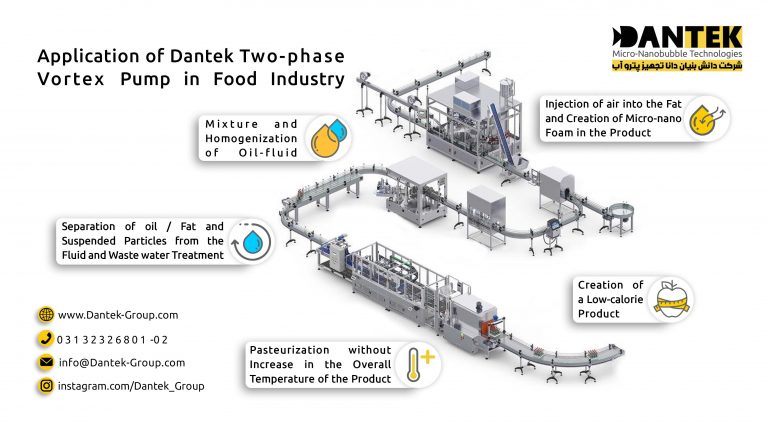

Dantek and Food Industries

A world of different foods and drinks with nano-bubbles

Micro-nano bubbles in food and dairy industries

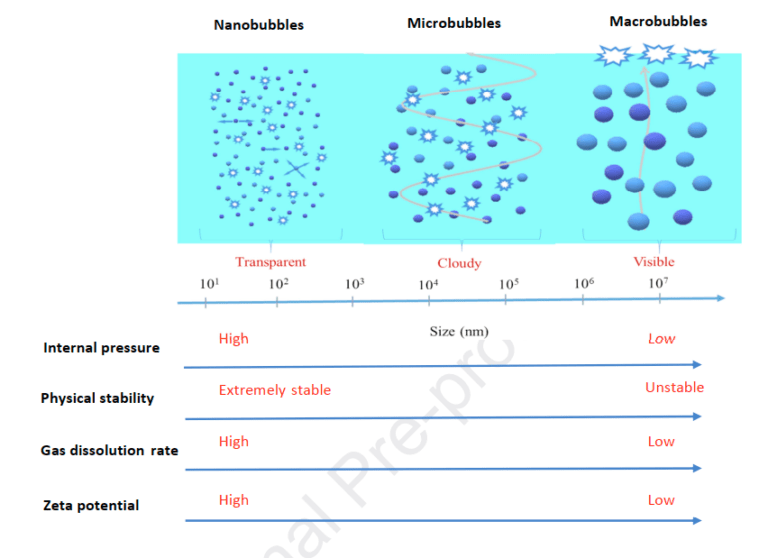

The use of micro-nanobubbles in the food industry is being extensively studied today. These bubbles, especially bubbles less than 500 nanometers in size, can be very attractive in the food industry and can be used in many applications. These bubbles have specific features in both surface micro-nanobubbles and bulk or volumetric micro-nanobubbles due to their very small size compared to ordinary and macro-sized bubbles, which are generally larger than 600 to 2500 micrometers and even larger.

Features of micro-nano bubbles in food industry

One of the most important features of micro-nanobubbles is the ratio of surface to volume in the gas-fluid interface, which increases chemical reactions and physical adsorption. In addition, excessive saturation of the gas in the fluid for a long time can cause the absorption and dissolution of large amounts of gas such as ozone and oxygen in the fluid and supersaturation.

On the other hand, due to the collapse of microbubbles, free radicals and hydroxyl ions (oH-) are formed. All of these features, along with their relatively low production costs and disinfection properties, and the small environmental impacts they leave behind, have made these micro-scale bubbles an attractive solution to a lot of challenging problems that have already been addressed to industries.

Micro-nano-bubbles in the food industry today have a variety of applications in the field of flotation with soluble air, cleaning surfaces without the use of detergents and separation of minerals. Also, the presence of micro and nano-bubbles in aquatic environments significantly affects the growth of lettuce and agricultural products such as brassica campestris.

Due to the great potential and applications of this size of bubbles, micro nano bubbles are expected to have many applications in the food industry. In fact, gas bubbles play a very important role in the stability of carbonated beverages, dough production (bread, pasta and biscuits), animal products (ice cream, cheese and cream), chocolate and sweets.

The size of micro nano bubbles in the food industry has started from 0.1 microns and has been reported up to 1400 micrometers. In recent years, foam-like behavior and gas phase have been extensively studied in the food industry and the quality of production and it has been shown to what extent it can affect the quality of the output product.

The applications of micro-nanobubbles in the production of gels, cream-based materials, carbonated beverages and fortified foods are being extensively studied. Especially in cases where stability, uniformity in distribution, new textures and increasing the productivity of the product are possible by using micro-nanobubbles. In addition, micro nano bubbles can be used in disinfection and washing of production lines.

Features of Micro-nano bubbles

Although micro-nanobubbles have different categories in terms of bubble size, they are generally called bubbles less than 200 nm, nano-bubbles, and bubbles between 200 nm and 10 μm micro-nano bubbles.Bubbles larger than 10 micrometers and less than 100 micrometers are also called micro-nano-bubbles.

Micro-nano scaled bubbles in bulk have properties, the most important of which include very long maintenance time in the fluid and no collision and the formation of larger bubbles with other micro-nano scaled bubbles, very high specific surface area, gas dissolution in the fluid more than the superior state Saturation, large negative zeta potential, the formation of free radicals and the release of high energy due to bubble collapse. Figure 1 shows these features.

Some of the characteristics of micro-nanobubbles include gas dissolution with very high efficiency and in supersaturated concentrations in the fluid, high and long-term stability in the fluid, having OH- ions and negative zeta potential on the surface.

Applications of micro nano bubbles in food industry

Due to the characteristics described for micro-nanobubbles, these very small bubbles have great potential for use in various parts of the industry, especially in the food industry. The followings are some of their usages.

Reduction of fluid viscosity due to micro-nanobubble injection

One of the potentials and applications of micro-nanobubbles in the food industry is their effect on reducing the amount of fluid viscosity. In the food industry, one of the important issues of dairy and non-dairy factories is the transfer of fluids with relatively high viscosity. Under these conditions, the amount of energy used to transfer fluid increases and on the other hand, increasing the viscosity has other effects on filtration systems and membranes used in this industry.

For example, in the dairy industry, clogging occurs by increasing the amount of milk protein and its concentration in the membranes of the filtration system. On the other hand, the use of chemicals to reduce this effect or add water to reduce the viscosity creates its own issues in the production process.

By injecting bubbles 100 to 1,500 nanometers in diameter into the milk, these tiny bubbles attach to the charged milk proteins, making it much easier for them to pass through the milk protein concentrator and standardization filters. When these micro- and nano-scale bubbles are injected into the fluid medium with suspended solids, especially solids with charged particles, these bubbles adhere rapidly to the suspended particles, reducing viscosity.

In addition, bubbles of this size act as a buffer between milk proteins, preventing these proteins from sticking together and helping to separate them.

The works which have been done in this field has shown that with the injection of micro nano bubbles, the amount of protein concentration has increased from 15% to more than 54%, and in addition, the amount of whey protein has more than doubled.

New condiments of the food world with micro nano bubbles in the food industry

Due to one of the main characteristics of micro-nanobubbles, which are very small in size (bubbles less than 10 micrometers), these bubbles have a very high potential in gas transfer to fluid and dissolution in fluid. These bubbles can cause the fluid to penetrate better into food and solid food products, which makes them very suitable for transferring flavor as a condiment to food products.

Compared to traditional marinating methods that require a lot of time (up to several days), the use of micro-nano-bubbles in the seasoning fluid can cause the seasoning to penetrate much more evenly and deeply and reduce the penetration time. For example, in conventional methods of flavoring boiled eggs, it takes 3 days for the liquid to penetrate the surface of the egg, while using micro-nanobubble water, this time is reduced to 5 hours.

Similarly, it takes 12 days to flavor soybeans, but this time is reduced to about 1-2 days by using micro-nanobubbles, which means an 80% reduction in the flavoring time of bean seeds [1 ].

Improving the texture properties of food and increasing its sensory properties using micro-nanobubbles in the food industry

Using enough gas or air in food preparation is known as aeration in the food industry.

Aeration to food improves various properties, some of which include changing the texture of food, improving taste, improving digestion, and improving the sensory quality of food.

For processed and aerated foods we can point to cream products, cotton candy and carbonated beverages.

The distribution of micro and nano-sized gas bubbles mixed with edible emulsifiers can be a substitute for the flavors and colors created by thermal and pressure processes during making food products.

In addition, increasing the rate of CO2 transfer in carbonated beverages and turning it into nano-bubbles, when dealing with the tongue, creates a sense of pleasure for the consumer.

The role of micro-nanobubbles in the food industry and promoting food healthiness

Today, with the use of micro-nanobubbles, it is possible to easily achieve high concentrations of gas dissolution in the fluid. Oxygen dissolution is one of these gases.

Recent research has shown that the presence of this gas as a water-soluble gas can increase growth in animals, fish and plants.The presence of dissolved oxygen also helps increase bone density.

Research in mice has shown that bone loss in these creatures is reduced by drinking oxygen-enriched water.

Today, there are ways to increase the amount of water-soluble oxygen to more than 40 mg / l and maintain this amount of oxygen for several months. In addition to oxygen, the dissolution of hydrogen is another topic that researchers are working on. Several properties of hydrogen such as antioxidant, anti-apoptotic and anti-inflammatory have received much attention. These properties can improve and protect the cells and organs of the body. Supplying water-soluble hydrogen is a very safe way to use it.

The only problem with this method is the very low dissolution of hydrogen in the fluid. This number is about 1.6 e-4 grams per 100 grams of water for hydrogen.

As mentioned above, one way to increase the concentration of soluble gas in a fluid medium is to use nanobubbles.Today, this type of water is commercially produced and marketed in one or two countries of the world.

The use of micro-nanobubbles in improving the crystallization and freezing conditions of food products

Freezing is one of the most common processes in the food industry. In this industry, the quality of freezing material can be increased by using new methods such as ultrasonic and freezing at high pressure. In these methods, it is always tried to make the size of ice crystals smaller and also to minimize the amount of freezing on the outer surface of the food. In this regard, micro-nanobubbles create cavities when they disintegrate, which can play the role of a good place for germination. The more of these germination points, the higher the freezing rate. Injecting CO2 into the gene results in the production of a very thin layer of bubbles known as impurities, known as the initial germination points of ice. The reduction in ice crystal size as well as the reduction in freezing time both depend on the appearance of the initial germination points and their number and size. On the other hand, it has been shown that the presence of bubbles in the system can lead to germination points, similar to the effect of ultrasonic ice production systems. Today, even research has been done on the injection of micro-nanobubbles in non-Newtonian fluids and its effect on freezing, and the results show a reduction in freezing time and a decrease in the temperature of the freezing process.

Foam breakdown in proteins

Another application of micro-nanobubbles in the food industry goes back to protein purification.

Purification of proteins is a cost-effective process on an industrial scale, which is mainly done by chromatography. New research has shown that CO2 nanobubbles (bubbles up to 100 nanometers in size) can be separated. In this method, by injecting nanobubbles into the fluid phase, the suspended hydrophobic material adheres to the nanobubbles and becomes like an elastic object in the aqueous medium. Due to the density, the nanobubbles attached to the hydrophobic material come to the surface and their concentration must increase at the surface and are separated in this way.

Cleaning surfaces and opening membranes of filtration systems using micro-nano bubbles

Elimination of microorganisms, disinfection of surfaces and descaling of membranes of filtration systems are other applications of micro-nanobubbles. In the food and beverage industries, disinfection is a very common process in most parts of production lines. In this regard, the use of micro-nanobubbles to clean surfaces has received much attention, including cleaning steel surfaces from protein, biofilm, carbohydrates and fats.

In general, steel and polypropylene pipes are widely used in the food industry, which are easily contaminated by viruses and other pathogens. Research has shown that the use of micro-nanobubbles in the food industry has eliminated pollution at a higher rate and reduced water consumption, therefore the use of water has been reduced by 60% and the elimination of pollution has almost doubled.

In addition to disinfecting micro-nanobubbles, their use in filtration and removal of clogging of various filters can lead to non-clogging and opening. AFM images taken of filters exposed to micro-nano-bubbles show that these filters are much less clogged and fulling, which could help to develop the application of filters in the industry.

Antimicrobial properties and disinfection of water by micro nano-bubbles in food industry

Reducing the amount of pathogens and organic contaminants using micro-nanobubbles is a case that is currently being studied by many researchers. This is due to the high rate of gas transfer to the fluid. Increasing the rate of O3 ozone gas transfer to water and increasing its diffusion, dissolution and stability causes a significant boost in disinfection properties of nanobubbles.

Research has shown that nano-ozone or nano-ozone bubbles with a size of 30 to 460 nanometers can maintain the amount of gas in the fluid for about 3 hours and increase the amount of dissolved gas to 10 mg per liter. However, with the use of macro bubbles, this amount has only increased to 0.64 mg per liter.

The study also found that the amount of methyl orange in contaminated water was reduced by 93 percent with the injection of micro-nano-ozone, while the reduction in macro-ozone bubbles was only 2.3 percent.

In addition to ozone, the presence of OH- and shock radicals due to the disintegration of nanobubbles can also be very effective in removing contaminants, viruses and bacteria. These features make nano-bubbles very suitable for use in fruit and vegetable washing, CIP lines and tank washing.